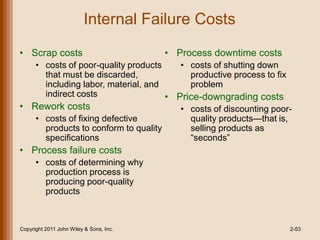

Built-in quality is also a core principle of the Lean-Agile Mindset helping to avoid the cost of delays CoDs associated with recalls rework and fixing defects. Intended to be applied only to manufactured products.

Defect counts and rework costs are two characteristics to measure.

. Which quality management concept does the inspection and corrective action represent. The characteristics of a product or service that bear on its ability to satisfy stated or implied needs. The requirements of a product or process can be categorized or given a grade that will provide a basis for comparison.

Manufactoring view Quality is conformance to specification. All resources are staffed by one employee. Performance features reliability conformance durability serviceability.

Undetected errors may lead to faults and eventually to incorrect behavior. Manufacturing perspective The _____ perspective defines quality as the totality of features and characteristics of a product or service that bears on its ability to satisfy given needs. Define quality from the customers perspective.

Understand why it is important to know that the different. A fault need not affect the reliability of a system. Maintainability is the measure of how long a service or service component can perform its agreed function without interruption.

Question 1 As a project manager overseeing a product launch you monitor and inspect the results to ensure the project is meeting the quality standards. TQM is one of the bedrock approaches to quality management. SAFes built-in quality philosophy applies systems thinking to optimize the whole system ensuring a fast flow across the entire Development Value Stream and makes quality.

Quality Planning Quality Assurance and Quality Control. Which of the following perspectives of quality judges quality of a product on the basis of consistency in meeting product specifications. Service Design Package is a key.

This activity is applied to the finished product and performed before the product release. The quality is determined by how well something meets the requirements of its grade. In this article I want to focus on approach that quality can be seen from different perspectives.

The second resource has a processing time of 6 minutes per unit. As defined by Investopedia it is a process through which a business seeks to ensure that product quality is maintained or improved and manufacturing errors are reduced or eliminated. Quality is both a perspective and an approach to increasing customer satisfaction reducing cycle time and costs and eliminating errors and rework using a set of defined tools such as Root Cause Analysis Pareto Analysis etc.

Chapter 1 Differing Perspectives on Quality Chapter Objectives After completing this chapter you should be able to. Be able to discuss quality dimensions. Achieving quality of conformance is product cost One of the top quality awards in japan is the Deming Prize An industry best level of quality service by a company tha t other companies.

At first glance each process group has an imposing list of inputs tools and techniques and. It focuses on how well the product was constructed in an effort to avoid the costs associated with rework during development and after delivery. For most people the term quality also implies good valuegetting your moneys worth.

The Cost of Quality. Unless evidence indicates otherwise a process is assured to be. In technical usage quality can have two meanings.

Recognize that different dimensions of quality. David Garvin in his book Managing Quality described the five perspectives of quality. The first resource has a processing time of 7 minutes per unit.

Quality 40 brings together Industry 40s advanced digital technologies with quality excellence to drive substantial performance and effectiveness improvements. Previous approval was not a one-off eg. The third resource has a processing time of 5 minutes per unit.

The findings from the firms sampled indicate a low to moderate learning capability which therefore can hinder their ability to implement best practice and work toward the. For example even low-grade products should still. You will see many of the components of TQM in other quality management approaches.

Its like I cant define it but I know when I see it. Transcendent - it means that quality is hard to define. Managing responses to threats.

Project risk management is best described as. A product or service free of deficiencies. A repair on a concession would be a one off approval as it is not valid for new cases.

A subjective term for which each person or sector has its own definition. Rework - Action that brings the product back into drawing specifications using previously and general approved methods. In a system two different failures may have different severities.

This approach is important because of the focus on a continuous cycle of improving the quality of a product service or process. The PMBOK Guide summarizes the tools and techniques associated with quality management in the table shown in Exhibit 1. Its quite blurred to define.

Two terms that have many interpretations because of the multiple definitions for the words assurance and control. The management accountant at Kaster Furniture Makers decides to include the fol lowing measures on their balanced scorecard BSC. Quality planning enables the project manager to manage the trade-off between customer expectations and budget.

You notice one standard is not being met and take corrective action to improve the standard. An international standard that describes a recommended quality system. I propose eight critical dimensions or categories of quality that can serve as a framework for strategic analysis.

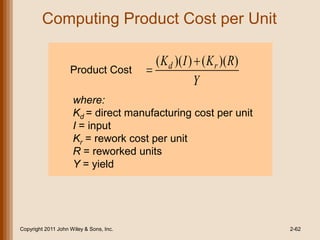

Communicate the seven different functional perspectives on quality. 3-Step Process with Rework Consider the following three-step assembly operation with quality problems. Project quality management is broken down into three main processes.

Quality assurancequality control QAQC. Maintainability is a measure of compliance to a contract by a supplier. Quality control verifies that the project deliverables conform to specification are fit for purpose and meet stakeholder expectations.

A system is necessarily more reliable after debugging for the removal of a fault. Customer satisfaction rework co sts on - time delivery average shopfloor personnel qualification and sales growth in lo cal markets These measures belong to which BSC perspectives. Give examples of the cost of poor.

Product view Quality is tied to inherent product characteristics. View Mid-Termpdf from CBA 01233 at New Era University.

First Example Picture For Error And Rework Information Download Scientific Diagram

Procurement Model For Reducing Rework Download Scientific Diagram

Causal Loop Diagram Of Design Error Induced Rework Download Scientific Diagram

0 Comments